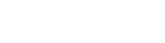

Ziliang Huang(2019)

Undergraduate College: China University of Geosciences (Wuhan) / Applied Chemistry

Research Direction: Modification of microstructure and mechanical properties of additive manufactured nickel based alloy

Research Content: Taking Hastelloy X (HX) alloy, the solid solution-reinforced nickel-based high-temperature alloy, as the object of study, the mechanism of influence of the significant anisotropy and microscopic defects of HX alloys prepared by SLM (selective laser melting) on the mechanical response of the alloy at macroscopic and microscopic scales is investigated by means of multi-scale and multi-dimensional structural and mechanical characterization. Moreover, the anisotropy of HX alloys prepared by SLM is attenuated through the introduction of modulating phases (such as nano-oxide particles). The method of preparing nickel-based high-temperature alloys by SLM process with excellent comprehensive mechanical properties is also explored.

Yuezhi Wang(2019)

Undergraduate College: Hunan Normal University / Physics

Research Direction: Research on optical 3D measurement technology and application of inner profile

Research Content: The mechanism and device for the three-dimensional detection of optical inner profile is developed to increase the inspection productivity of field engineering. The high-resolution optical detection imaging system which applied to the inner surface of the object (low F number limits the available depth of field), and 3D reconstruction of the inner surface of the object based on the optical imaging method are both investigated. Furthermore, the algorithm for data analysis on the generated 3D point cloud is also developed to obtain the internal structural parameters of the detected part.

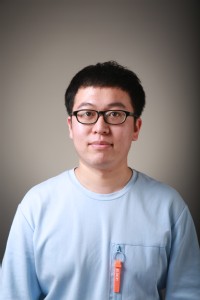

Yu Xuan(2019)

Undergraduate College: Southwest Jiaotong University / Materials Science and Engineering

Research Direction: Strengthening and toughening design and preparation of metal materials based on advanced powder manufacturing technology

Research Content: The multi-scale design for composition and microstructure of dissimilar alloy is investigated and implemented by SLM (selective laser melting) process, since SLM technology can provide the design freedom and also brings self-annealing, diffusion of alloy elements and phase transformation during its in-situ alloying. The parameters of the SLM process and the heat treatment methods are elaborately controlled to construct the distribution of multi-scale microstructure at regional or hierarchical levels. More importantly, the breakthrough design of strength-toughness trade-off compared with traditional metal materials is explored by advanced powder manufacturing technology. The final goal of this research work is to prepare high-performance metal materials with excellent performance for engineering applications based on the breakthrough design.

Huizhong Bai(2020)

Undergraduate College: Huazhong University of Science and Technology / Optoelectronic Information Science and Engineering

Research Direction: Research on infrared detection technology for defects during film cooling hole manufacturing process

Research Content: The micro/mesoscopic defects in materials are detected by infrared detection. Especially, the pulse infrared detection and phase-locked infrared detection technology are studied. The industry application of infrared detection technology in on-line defect detection of film cooling holes and thickness measurement of thermal barrier coating of aero-engine turbine blades is developed.

Jiaqiang Chang(2020)

Undergraduate College: China University of Petroleum / Material Chemistry

Research Direction: Gradient design and performance control of nuclear steel based on directed laser deposition process

Research Content: A SA316L/SA508-3 gradient material for nuclear power application is prepared by directed laser deposition. The effects of gradient structure design and deposition parameters on micro-structure and mechanical properties are mainly studied through analyzing the results of multi-scale structure characterization, in-situ mechanical experiment and stress corrosion tests. Moreover, the transfer function of gradient design to microstructure and mechanical properties is also explored. Furthermore, SA316L/SA508-3 gradient material with excellent comprehensive performance is tried to obtain through optimizing gradient structure and deposition parameters, which will make it possible to apply this gradient structure in nuclear power industry.

Shuwen Chen(2020)

Undergraduate College: Soochow University / Nano material and technology

Research Direction: Ceramic 3D printing

Research Content: The research is on the additive manufacturing of oxide ceramic based on SLA technology. The process of additive manufacturing ceramic is optimized through simulation and rapid iteration of DOE. Oxide ceramic slurry suitable for SLA technology and post-treatment processes including debinding and sintering is investigated. The mechanical properties of additive manufacturing ceramic product is evaluated and the transfer function of mechanical properties, manufacturing process and microstructure is analyzed to provide theoretical and experimental foundations for the engineering application of additive manufacturing ceramic product.

Yixuan Chen(2020)

Undergraduate College: ShanghaiTech University / Chemistry

Research Direction: Application of machine learning in melting pool monitoring and closed-loop control during additive manufacturing process

Research Content: Based on the setup of a visible light and infrared coaxial imaging system, the influence of process parameters on the quality of melted parts is studied through online monitoring the shape of melting pool during additive manufacturing process; and consequently, the closed-loop control of the process based on machine learning is demonstrated. Furthermore, the correlation between the process parameters and the defects of parts obtained by additive manufacturing process is established based on the neural network algorithm, by monitoring the energy reflected by the melting pool during laser melting the selected area. As the industry application, the theoretical basis will be provided for achieving the quality consistency of the parts made by additive manufacturing process.

Li Hao(2020)

Undergraduate College: Harbin Institute of Technology / Mechanical Design manufacture and Automation

Research Direction: Digital production line for electric discharge machining of film cooling hole

Research Contents: A digital platform of the EDM production lines for drilling turbine blade cooling holes based on EMQ X, TDengine, MQTT and other digital technologies is developed. By collecting, storing and analyzing the manufacturing and inspection data in real time, the manufacturing process is monitored, and the first part yield is improved. By monitoring the status of the machines in real time, the health management and predictive maintenance of EDM machines are realized for shop automation and digitalization.

Jayden Li(2020)

Undergraduate College: Tongji University / Vehicle Engineering (Automobile)

Research Direction: Dynamic calculation and the simulation of microstructure evolution for melting pool during additive manufacturing

Research Content: Combined with experimental technology, the formation and evolution of the melting pool during the additive manufacturing process are studied through non-steady state, multi-phase flow and multi-physics numerical simulation methods. Focusing on the simulation of microstructure evolution during the remelting and resolidification process, the unique transient temperature superposition field and in-situ heat treatment effects are figured out. Moreover, the nucleation parameters of the alloy based on experimental data are figured out to provide a physical basis for controlling the evolution of the grain structure and customizing texture during the process of additive manufacturing in industry.

Xiaochen Li(2020)

Undergraduate College: Qinghai University / Material & Science and Engineering

Research Direction: Grain boundary engineering of Inconel 718 superalloy obtained by selective laser melting

Research Content: The project aims to investigate the category, shape of grain boundary and the precipitate at GB on the mechanical behavior of Inconel 718 , which is manufactured by selective laser melting (SLM), using multi-scale characterization, in-situ mechanical test at room temperature or high temperature and digital image correlation (DIC) technique. The work focusses on the optimization of process window of SLM and post-heat treatment parameters, to modify the characteristics of grain boundaries and then obtain excellent mechanical properties, especially the fatigue performance.

Zijian Li(2020)

Undergraduate College: Shandong University / Automation

Research Direction: Force control technology for blade automatically grinding system

Research Content: High-precision closed-loop control system for grinding force and positioning of grinding head during automatic blade (compressor blade, turbine blade, et.al) grinding process is developed to solve the key issue of grinding quality caused by the low control accuracy and stability of grinding force. Main focus is the development of embedded high-speed and high-precision linear motor torque, position acquisition system, fast demodulation algorithm of force and position. Furthermore, the accurate force-position hybrid control system applied in robot high-precision grinding process is established.

Haineng Ma(2020)

Undergraduate College: Southwest Jiaotong University / Material Forming and Engineering

Research Direction: Research ontechnology of intelligently grasping objects based onrobot and machine vision

Research Content: Targeting the needs of identifying and grasping objects under complex environments, the unified management and data platform is developed to support robots based on ROS, machine vision and three-dimensional scanning technology. Especially, matching algorithms of robots between three-dimensional space and two-dimensional images are developed to generate optimal grasping position of targeted parts and also plan the tool path of robot grasping to prevent collision, which could demonstrate the concept of intelligently grasping objects under complex environments.

Cheng Peng(2020)

Undergraduate College: Huazhong University of Science and Technology / Optoelectronic Information Science and Engineering

Research Direction: Development of software platform for turbine blade profile measurement

Research Content: A software platform for blade profile analysis is developed to be implemented in blade inspection system designed by CASE. By sensing data stitching and profile extraction of blade, the key features, such as profiles of leading and trailing edges, blade profile thickness, chord length etc, are obtained. Furthermore, the rapid and accurate inspection, analysis and quality evaluation of the dimension and deviation distribution on key features of blade profile are also demonstrated.

Ning Wang(2020)

Undergraduate College: Central South University / Material Science and Engineering

Research Direction: Ceramic additive manufacturing

Research Content: Additive manufacturing processes and performance of non-oxide ceramics (SiC, Si3N4, etc.) based on SLA (stereo lithography appearance) are investigated. Due to the nature of non-oxide ceramics, the slurry of them is difficult to cure satisfactorily. Obtaining the curing slices with sufficient strength and thickness during SLA process is the main focus. In addition, ascertaining the relationship between microstructure, defects and manufacturing process is as well as investigated. The expected goal is to develop the whole additive manufacturing process of non-oxide ceramics suitable for SLA, including slurry preparation, printing, debinding and sintering.

Youcheng Wang(2020)

Undergraduate College: Dalian Jiaotong University / Measurement and Control Technology and Instrumentation Program

Research Direction: Non-linear ultrasonic inspection for mechanical properties of parts made by additive manufacturing process

Research Content: Aiming at parts made by additive manufacturing process, high-energy nonlinear detection and analysis methods for fatigue strength, residual stress and other mechanical properties are investigated. Especially, high-speed data acquisition system and fast analysis algorithm of high-energy nonlinear ultrasonic signal are developed, and high-energy nonlinear ultrasonic database of additive manufacturing parts is also established. Furthermore, deep learning algorithm is applied to improve the detection sensitivity and accuracy.

Yuancheng Wang(2020)

Undergraduate College: Northeastern University & Mechanial Engineering

Research Direction: Tool path design and optimization of an automatic blade-grinding system

Research Content: Curved surface deformation and poor processing consistency are main pain points during manufacturing compressor and turbine blades in China, especially it is difficult for the robot-grinding-process to guarantee the quality of surface profiles. In order to solve this problem, the adaptive tool path planning algorithm and the post-program for blade-grinding robots are investigated through combining CAD and CAM technologies with the measurement data of grinded blade profiles. Simultaneously, the adaptive zone-grinding function of the robots is investigated. Furthermore, the efficiency and quality of grinding process will also be optimized.

Ninglu Zhang(2020)

Undergraduate College: Northeastern University / Mechanical Engineering

Research Directions:Research on virtual pre-assembly technology of micro gas turbine

Research Contents:Virtual simulation prediction for assembly quality of micro gas turbine are investigated. The whole machine assembly dimension chain model and simulation analysis based on the design tolerance of parts and fixtures are established to optimize the design tolerance and allocation. The influence of deformation of thin-walled parts such as combustion chamber on the assemblability of the whole machine and the influence of clearance on dynamic balance at high speed are analyzed. Through the measurement of the actual size and three-dimensional contour parameters of the machined parts, the simulation and prediction model of the whole machine assemblability based on the measured data is established, and the repair and assembly optimization strategy of the parts is given according to the simulation results. Accurate prediction of assembly quality and visualization of assembly deviation of micro gas turbine are realized.

Xun Zhang(2020)

Undergraduate College: Dalian University of Technology / Mechanical Design and Manufacturing and Automation

Research Direction: Rotor design of high speed permanent magnet motor

Research Content: A rotor of direct drive high speed permanent magnet motor for a 100 kW gas turbine is designed, and the influence of thermal stress, magnetic steel distributed parameters and centrifugal force on rotor performance is analyzed by using finite element method. Moreover, the analysis method and design procedure of carbon fiber sheath are established. The rotor structure is also optimized. Finally, the design process specification of high speed motor surface type rotor is established.

Yu Zhang(2020)

Undergraduate College: Dalian University of Technology / Energy and Power Engineering

Research Direction: Structure optimization and property control of superalloy made by additive manufacturing process

Research Content: The research focuses on high temperature superalloy for gas turbine application. Reasonable composition design is investigated at the first step, and then the effect of 3D printing multi-scale structure made by selection of laser melting (SLM) and/or directional energy deposition (DED) on the mechanical response of superalloy is analyzed. In detail, superalloy sample applied for gas turbine will be prepared by additive manufacturing process. Combined with in-situ characterization and mechanical experiments, the mechanics performance is tested, and the microscopic mechanism is investigated. Finally, the multi-scale structure design and process optimization for additive manufacturing are implemented to optimize the properties of superalloy applied for gas turbine.

Zhao Zhang(2020)

Undergraduate College: Harbin Institute of Technology / Mechanical and Electronic Engineering

Research Directions: Stator design for high-speed permanent magnet motor

Research Content: Stator of direct drive high-speed permanent magnet motor in a 100kW gas turbine is designed. Especially, the electromagnetic simulation is developed by using the finite element method. The Iron loss and copper loss of stator are analyzed. Furthermore, the overall structure of motor, winding distribution and topological shape of silicon steel sheet of stator are also designed.

Rongfa Zhao(2020)

Undergraduate College: North China Electric Power University ( BeiJing ) / Energy and Power Engineering

Research Direction: Design and verification of advanced heat exchanger made by additive manufacturing process

Research Content: The triple periodic minimum surface structure (TPMS) in advanced heat transfer and cooling design is mainly investigated. The DIC strain measurement system combined with universal testing machine is used to evaluate the stress-strain curves of materials with different TPMS structures, and the stress distribution and failure mode of periodic / aperiodic structures under quasi-static compression conditions are analyzed by simulation numerical analysis. A test rig is built to verify the change of extreme pressure loss of TPMS heat exchange efficiency, providing a theoretical basis for the new generation of additive manufacturing heat exchangers.

Zhengnan Zhao(2020)

Undergraduate College: Sichuan University / Mechanical Design and Manufacturing and Automation

Research Direction:Based on the concept of integrated structure and function design of additive manufacturing, the variable section design of hydraulic valve body is investigated. Firstly, fluid simulation technology is applied to discuss the influence of variable section design on the convection resistance and also the influence of fluid pressure on the hydraulic valve body. Secondly, structure simulation technology is applied to optimize the design of hydraulic valve body. Finally, the influence of additive manufacturing technology on the overall performance of hydraulic valve body is also investigated.

Zhe Zheg(2020)

Undergraduate College: Nanjing Tech University / Computer Science and Technology

Research Direction: Research on automatic detection system of aviation route defects based on deep learning

Research Content: An automatic detection system for aviation pipeline defects based on deep learning is designed and implemented to solve the problem of the scarcity of industrial defect images. A new generation of generative adversarial network is proposed to generate defect data that approximates the real scene, combined with traditional image fusion algorithms (Poisson fusion, etc.). The model compression method (neural network architecture search, model distillation, etc.) is adopted to achieve the high efficiency and high precision requirements of the visual inspection system in the actual industrial scene.