On the evening of Wednesday, November 30, Mr. Xie Guangping from CASE Lab of College of Creative and Art brought a lecture - 3D digital technology in industrial design to the students of Industrial Design (Smart Design Direction).

This event gave the students a deeper understanding of the cutting-edge digital technology and the future potential of the industry, and encouraged them to think and participate in the breakthrough innovation in the field of high-end manufacturing and design, and creative arts together.

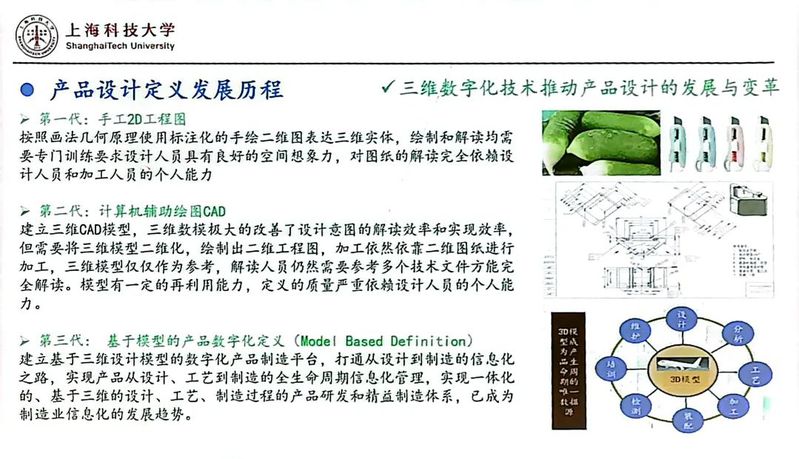

Product Design Definition

Mr. Guangping Xie first mentioned three shifts in the definition of product design. The first generation is manual 2D engineering drawings, which are hand-drawn 2D drawings to express 3D entities through geometric principles, which requires special training to complete the drawing and interpretation; the second generation is computer-aided drafting CAD, which greatly improves the efficiency of drawing interpretation; the third generation is the digital definition of products based on models to achieve integrated information management, which is the future development trend of manufacturing information.

Professor Xie also mentioned, "Industrial design is a system engineering, which should not be limited to form design, but should analyze and consider demand, process, cost, structure, human factors engineering, etc., and design a comprehensive solution, involving a multifaceted knowledge system. Digital technology can enhance the industrial designer's ability to control the product development process and also free the designer from the traditional hand-drawn design."

This shows that the future of 3D digital technology can revolutionize the design concept of industrial designers and adapt to the trend of green design and fashionable personalized design concept, which also brings a lot of inspiration for the students.

►►►

3D digitization and point cloud data

To understand the 3D digitizing technology, you first need to have a general knowledge of the whole process of 3D point cloud data processing. Mr. Xie clearly divided the processing process into five steps, which are: point cloud acquisition, point cloud filtering, point cloud processing, data segmentation and point cloud data modeling. And for these five steps, Mr. Xie also made a brief introduction of concepts, principles and main methods respectively. The slightly obscure concepts in the pictures and examples seem to be not as difficult to understand as we thought before.

As for the modeling direction, which is closely related to industrial design students, Mr. Xie also proposed two thinking paths: forward modeling and reverse modeling.

Q:

What is forward modeling and reverse modeling

Forward modeling:We are most familiar with sketch to CAD model

Reverse modeling:First the physical object and then the CAD model, i.e. from the sample to the CAD model

Although the two approaches seem to be completely opposite, often for the sake of the final product, mixed forward and inverse modeling is the most widely used modeling method in engineering. Starting from the point cloud data of the sample, then reverse modeling through solid features with some complex surfaces, and finally arriving at the final solid modeling through Boolean operations.

Combined with 3D printing technology, inverse modeling is not only often used in industrial workshop production, but also has a great contribution to the medical aspect and architectural field.